How the AWTI Process Can Accelerate Your Small Cell Deployments

Small cell deployments are a big part of 5G network new deployments. Although the deployment processes of small cells and macro cells have some stages in common, there are also some foreseeable differences.

Small cell deployment:

- Is more of a volume game: less specific hardware, more modular, and less customized architectures

- Requires greater “deployment flexibility”

- Requires Commissioning and Integration (C&I) on much higher scales

- Pre-integration becomes more important, for reduced time of installation in more time constrained working situations, i.e., the concept of “Ready-to-Install-Small-Cell-Solutions”

- Requires more coordination to optimize the usage of crew, equipment, street closures, etc.

When regulatory and site permissions have been obtained, the next challenge is to install the cells in an efficient, quick, and affordable way. Physical cell installation in large scale Heterogeneous Networks (HetNet) deployments can be a challenge due to very large numbers of cells requiring integration, setup, and configuration in difficult places. These places are either dense urban areas (i.e., for 5G cell densification) with restricted time and presence in the cities’ right of ways, or indoor areas with restrictions of their own.

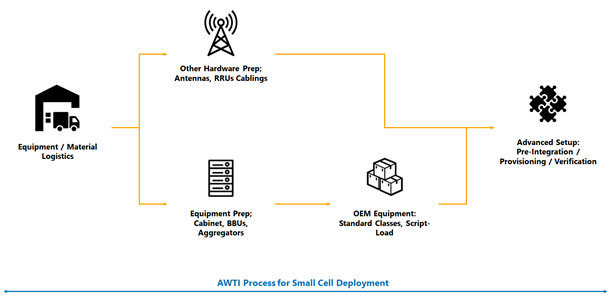

The Assemble, Wire, Test, and Integration (AWTI) process, as part of an end-to-end small cell deployment, can help operators overcome some of these challenges.

This diagram shows a simplified AWTI process for small cell deployment.

AWTI increases speed-to-market and increases overall deployment quality with:

- Lower labor costs

- Faster installation times

- Reduced shipping through material consolidation

- Less waste to be disposed of from sites

- Elimination of excess material

- Stronger adherence to standards

- Plug-and-play installation

- More consistent and reliable close-outs

- Elimination of out-of-box failures

The AWTI Process

Equipment/Material Logistics

The AWTI process provides equipment and material logistics via market or project warehousing:

- Improved project alignment of equipment and materials to meet construction start dates

- Fewer delays for replacement equipment and/or Out-of-Box Failures (OBF)

- Material cost savings via scale or volume discounts, transportation, etc. (i.e., wood or metal poles, antennas, mounts, etc.)

- Improved market inventory control

- Reduced client’s management needs, reporting, coordination, etc.

- Script load to OEM equipment

- Radio inventory control and coordination

- Coordinate radio pre-integration matched to construction schedules

- Labor: Pre-integration can significantly reduce traditional on-site deployment time. By slashing onsite installation time and eliminating the need for multiple on-site inspections, mobile operators can build many cell sites in the time it once took to build one.

- Shipping: All components arrive in one shipment, avoiding separate shipping costs. Direct-to-site shipping completely removes all warehousing costs for the operator.

- Commissioning: Commissioning becomes a matter of simply connecting the network and power to the pre-integrated platform. All the major pre-integrated components are installed and tested before, so this activity does not have to be performed in the field.

- Standardization: There is a simple, standardized method of interconnecting the platform components together as well as to the carrier network and the tower-top components.

- Maintenance: Maintenance is much simpler and less expensive because technicians know there is a standard platform with connections and components in the same place.

- Higher Quality: Pre-integrated components are connected and tested at the factory. Contractors and mobile operators no longer must deal with the effect of connecting complex equipment in field conditions, and workers with junior-level skills can handle the deployment without fear of reducing quality.

- Lower Complexity: The pre-integrated platform is a single system with one stock-keeping unit (SKU), so it is easier to order and transport. Rather than having to deal with a dozen or more vendors, there is one vendor to deal with, one purchase order to issue and one shipment to track.

- Greater Flexibility: With a pre-integrated solution, individual cabinets can be upgraded to accommodate extra equipment or more highly integrated systems.

Equipment Preparation: Cabinet, BBUs, Aggregators

The main equipment including, cabinets, Base Band Units (BBU) and aggregators, are prepared and the correct connections are tested here.

Other Hardware Preparation: Antennas, RRUs, Cablings

Other hardware like tower tops including antennas, Radio Remote Units (RRU), and required cablings (fiber, ethernet, power), with their pre-integrated configurations are tested and prepared here.

OEM Equipment Standard Classes, Script Load

The use of standard classes of equipment (if applicable) and their installation rules can ease the burden of installation, operations, and maintenance. The installation rules attached to the equipment class indicate the level of knowledge and skills the workers require to make the installations. Per-class deployment recommendations can also reduce the complexity of initial commissioning and following Operations and Maintenance, reduce the deployment and its associated maintenance costs. This function also provides:

Advanced Setup: Pre-integration / Provisioning / Verification

Cell installation in very large scales can be a challenge due to permits needed, equipment transport and installation, and large numbers of cells requiring set-up and configuration. Lean cell site approaches, in which there is considerable advanced base station set-up/provisioning, are carried out here to avoid site disruption and minimize time to perform installation.

The AWTI process offers these business advantages:

CapEx Savings: There are several areas of savings which can cut deployment costs considerably.

OpEx Savings: Since the product is standardized, operating costs are reduced.

Quality Improvement: In addition to cost savings, pre-integrated platforms offer many other benefits:

As mobile operators’ network densification projects proceed, they will have to build hundreds of thousands of new cell sites. Rather than wasting time building customized iterations of cell sites, these operators should look to pre-integrated solutions to save time, reduce OpEx and CapEx, and ensure the highest quality.

To learn more and discover how KGPCo’s Assemble Wire Test and Integrate solution can work for your small cell builds contact the KGPCo Wireless Service team.

Learn More